No products in the cart.

Adventure is around the corner.

Get exclusive news about Tuffcycle products, innovation & events.

[newsletter_signup_form id=1]

Most of us want to live a “Champagne lifestyle” but only have a “Beer budget”. At TUFF we are trying to close that gap by offering the best wheels we can at more affordable prices. This can be seen with our new EXO wheels with MATRIX carbon fiber spokes. These wheels have dropped the weight of the set to less than the high-end brands’ wheels, while we have kept the price significantly lower.

But the advanced technology we use is not limited to just the EXO range of wheels. Because we have such a close relationship with the best factories available we get to incorporate all their latest developments into ALL our rims. A lot of this tech is not yet even available in the rims made by the “big names” in carbon fiber rims that cost significantly more.

So what is so special about our rims?

Using advanced aerospace composites technology; our designs equalize the stresses throughout the carbon fibers. Careful application of layup of carbon sheets allows the best balance between the strength and weight. With years aerospace experience and professional finite element structural analysis, we optimize the layup for strength, weight, and to consider braking loads so our wheels still elevate the performance of talent athletes and elevate the safety of their equipment.All this care we put into design, layup, and manufacture results in improved strength to weigh and quality levels than most other rims on the market.

Smooth molding technology means the Carbon fibers in our molding process do not get wrinkled. This means no damage to the carbon fiber structure and the fibers remain straight and better able to carry loads. The surface will not produce pores and means we don’t need to need paint rims.All this care we put into design, layup, and manufacture results in improved strength to weigh and quality levels than most other rims on the market.

Our preference is to make rims of unidirectional carbon fiber without any coating. This reduces excess filler material as the fibers are all laid flat and not woven which causes small pockets of low strength resin everywhere. The use of unidirectional sheets of carbon fibers increases strength to weight ratios considerably. It also results in the least porosity of the molded material ensuring a perfect surface finish again without any painting or coating required for appearance reasons. Meanwhile, no coating means no surface grinding. The grinding applied to other brands of rims will result in damage to the surface fibers.

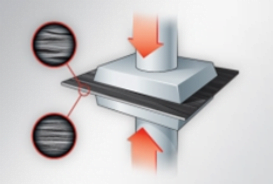

The newest technology we are applying to our rims is smooth molded holes with no drilling. The molded holes result in a rim with no increase in weight over traditional drilled spoke holes, but increased strength by around 60%. In each spoke hole is embedded a thin metal cap which is molded into the structure during manufacturing. The cap helps distribute the load from the spoke nipple over a larger area decreasing the effect of the stress concentration. Additionally as the hole in the carbon fiber structure is molded in, the fibers are continuous and not cut during drilling. With no interrupted fibers in the structure and better load distribution our rims maximize strength and stiffness without adding weight.

TUFF products are made using a blend of T800 and T700 fibers and woven to our specifications. T800 is stiffer, but tends to be brittle. T700 is also cheaper. By using the right layups, strength and stiffness in the right places can be combined to allow light weight and performance.

Precision tooling creates rims that are round and straight directly from the tool. Strict quality control is still employed to ensure even the smallest defects do not make it to the customer

Precision machinery is used to ensure accurate drilling of spoke holes This is vital not only for spoke holes, but used for bottom brackets, headsets, and bearing seats in suspension frames.